Speed up to 200pouch/min

Rotary Sealing Mechanic

Maximum Working Width in 200mm

· Name of machine: fully automatic wound dressing manufacturing and packing line

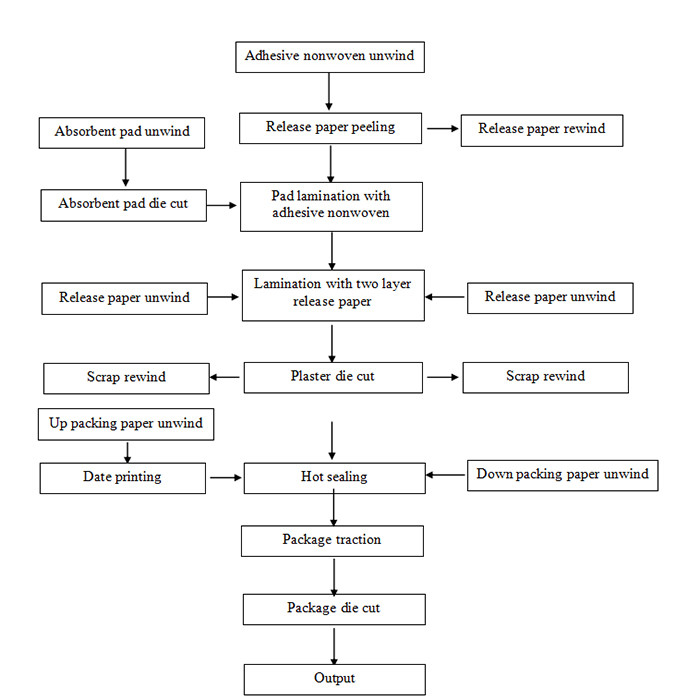

· working principle

· voltage: 380v, power 10.60kw

· MONTION CONTROLLER control system connection with touch screen

· production speed: 180pouches/min (for 60x80mm)

· maximum working width of plaster: 350mm

· maximum working width of packages: 450mm

· sealing method: roller sealing

· 3 groups rewindmechanic adopts magnetic powder clutch tension control

· 5 groups unwind mechanic adopts magnetic powderbraker tension control or fully automatic constant tension controller (for customer selections)

· photoelectric eye for printing art-work on up packing paper (for detect the knife to cut from correct position)

· servo motor controlling mechanic for other stations

- basic materials traction mechanic

- pad traction mechanic

- pad cutting die mechanic

- Plaster traction mechanic

- Plaster die cutting mechanic

- hot sealing mechanic

- packages traction mechanic

- packages cutting die mechanic

· photoelectric eye: 6pcs

machine auto stops during each raw materials shortage

· approx. size and weight: 3300x1080x2000mm, 2400kg

· machine Body: steel, packed with stainless steel and raw materials connection part adopts stainless steel, and some by chromate treatment or Aluminum.