ForTegaderm with Windows

Making and Packing Online

Max working width 140mm

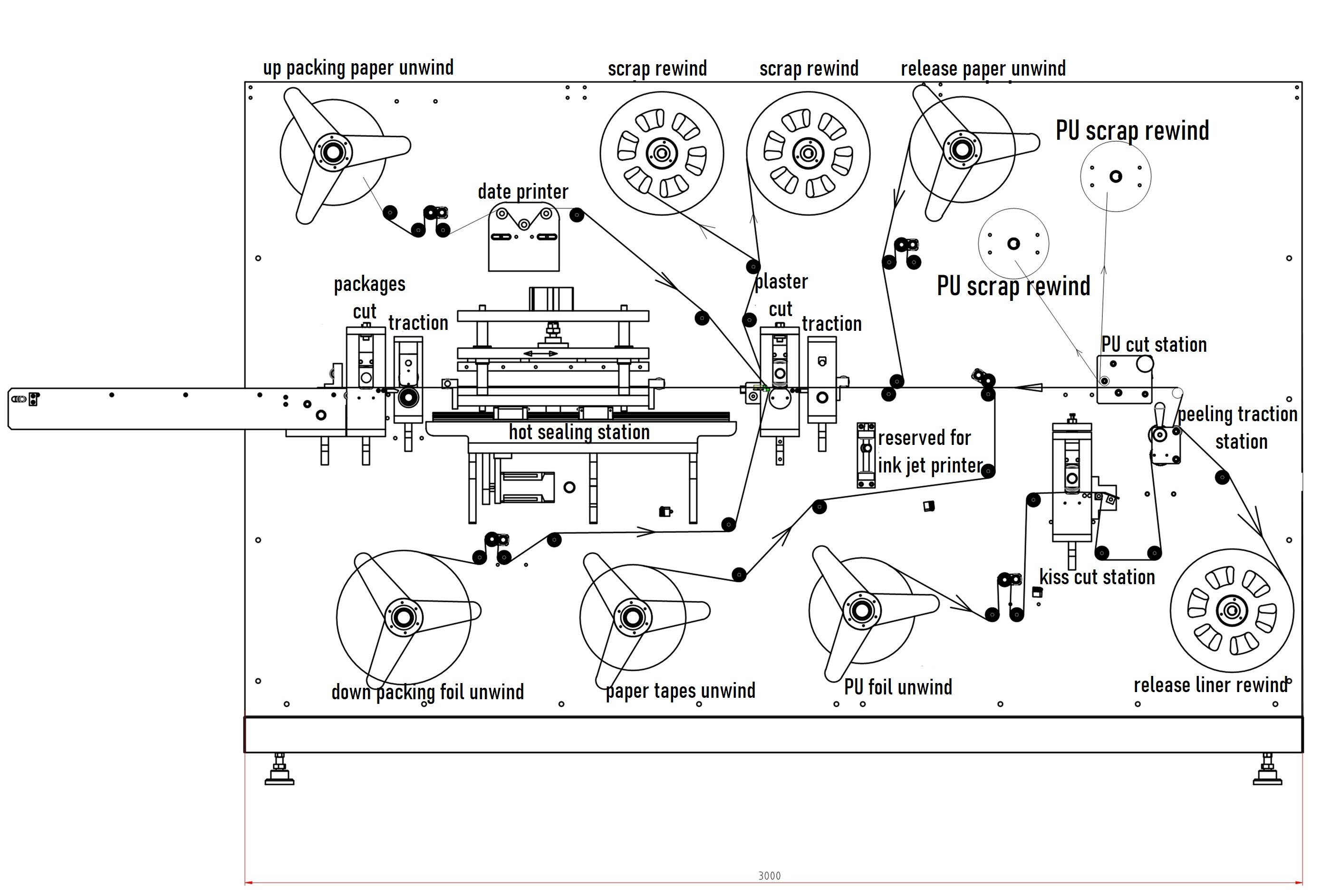

· Name of machine: fully automatic IV cannula dressing manufacturing and packing line

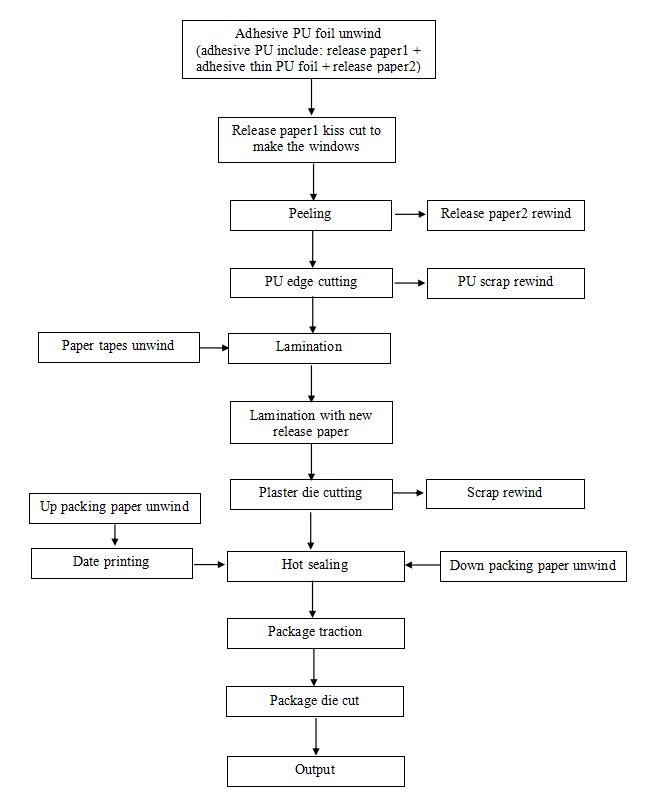

· working principle

· voltage: 380v, power 9.5kw

· MONTION CONTROLLER control system connection with touch screen

· production speed: 6-10meters/min

· maximum working width of plaster: 150mm

· maximum working width of packages: 250mm

· 5 groups rewind mechanic adopts magnetic powder clutch tension control

· 5 groups unwind mechanic adopts automatic constant tension controlling

- basic materials unwind

- release paper unwind

- paper tapes unwind

- two packing materials unwind

· photoelectric eye for printing art-work on up packing paper (for detect the knife to cut from correct position)

· servo motor controlling mechanic for other stations

- basic materials traction mechanic

- kiss cut mechanic

- plaster traction mechanic

- plaster die cutting mechanic

- hot sealing mechanic

- packages traction mechanic

- packages cutting die mechanic

· photoelectric eye: 5pcs

machine auto stops during each raw materials shortage

· approx. size and weight: 3000x1050x2080mm, 1650kg

· machine Body: steel, packed with stainless steel and raw materials connection part adopts stainless steel, and some by chromate treatment or Aluminum.