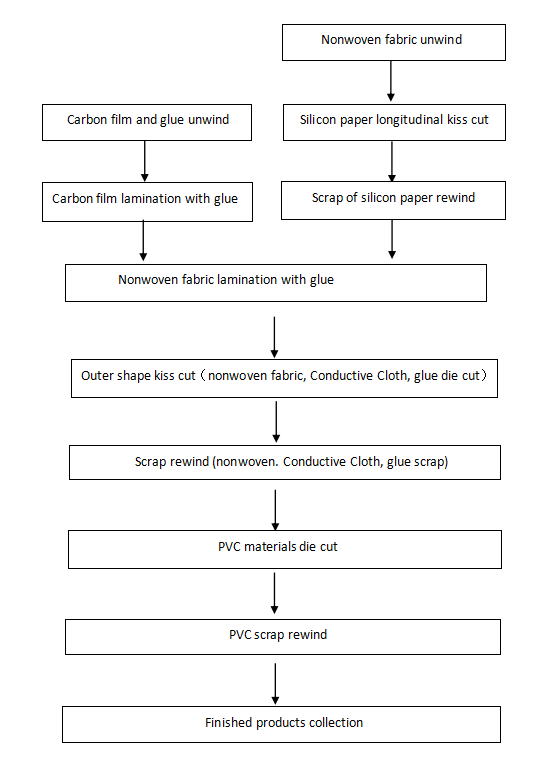

· Working principle:

· Including: 3 groups unwind mechanic, 3groups scrap rewind mechanic, 1group lamination and traction mechanic, 3groups rotary die cutting mechanic, 1group finished products collection mechanic, 1group products counting mechanic, and electric control system (includes automatic tension controller, electrical centralized control system)

· Unwind mechanic

Adopts automatic photoelectric sensor to detect tailings and has the function of pre-deceleration and shutdown

· Rewind mechanic

Adopts inflatable pneumatic shaft clamp feeds directly and is driven independently by servo motor. The tension is controlled independently.

· Tension controlling mechanic

The multi-channel computer automatic tension control system controls the tension of each group independently, and the tension is constant in the whole process. The system can automatically compensate for the roundness error, diameter change, speed change or other factors affecting tension stability of raw coil in the production process, so as to achieve the goal of automatic control of constant tension.

· Lamination mechanic

Adopts double roll press, steel, flexible combination, independent drive by servo motor, high synchronization accuracy, digital adjustment of synchronization compensation value, easy to operate

· Longitudinal cutting mechanic

The cutting depth of the blade can be adjusted at will, so as to avoid the phenomenon of impermeability or cut-off caused by the different thickness of the non-woven separating paper, and to facilitate the cutting of various specifications of materials (nonwoven fabric+ double face glue + silicon paper)

· Die cutting mechanic

Adopts rotary die cutting design, driven by servo motor, the cutter blade is designed according to the product requirements, and the product die cutting is completed twice respectively. The die cutting accuracy is high, the replacement of die cutting rollers is simple and the operation is stable. The two pairs of die cutting rollers at the back are equipped with phase regulators. The transverse position of the die cutting rollers is fine-tuned by position regulators, and the adjusting range is 10mm, which facilitates the alignment and alignment of the die cutting.

Maximum raw materials width: 260mm

Maximum unwind and rewind diameter: 400mmMechanic speed: 30 meters/min Maximum working speed: 4-10 meters/min Die cutting accuracy: ±0.2mmTotal power: 8KwMachine size: 4000×1200×1800mm